Professional Grade Dead Blow Hammers

No matter how tough your job is, these hammers won't let you down!

FME Products

Lifetime Warranty

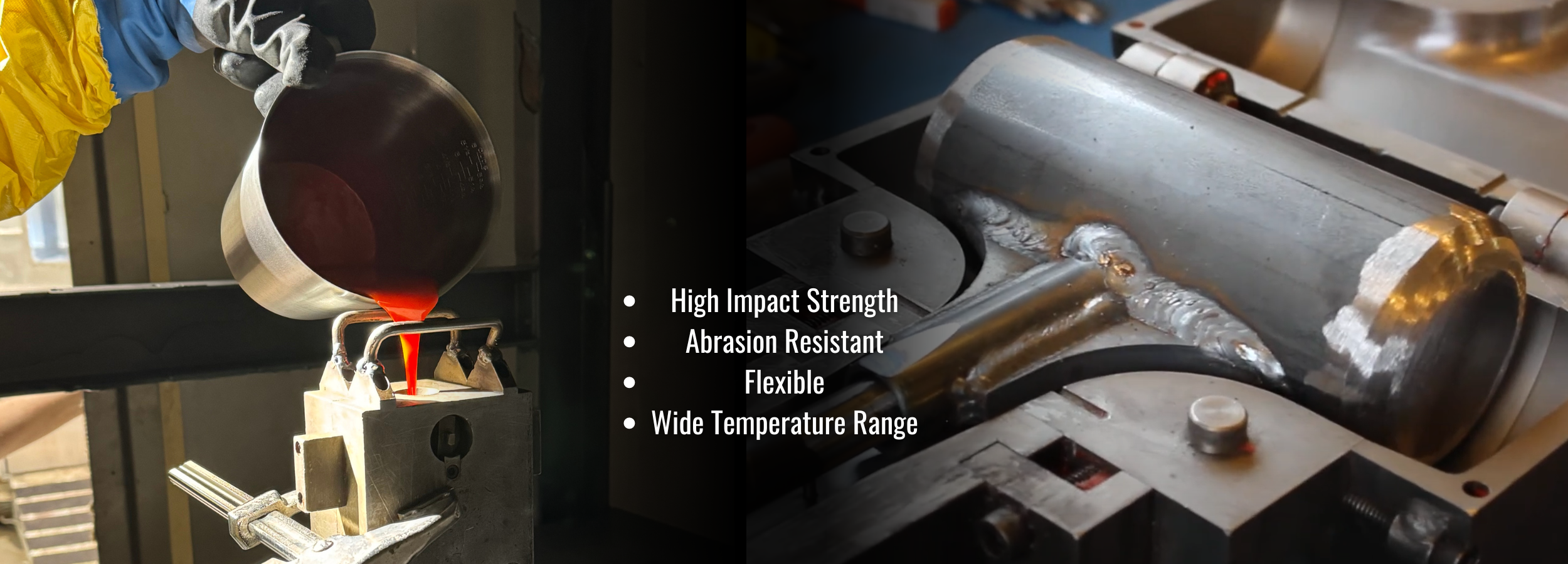

Our 100% fully welded steel construction is guaranteed to last the life of the hammer. No steel shot will ever leak out of our hammers.

Commercial Grade Hot Cast Poly

Collections

-

Dead Blow Hand-held Hammers

Discover the ultimate tool for precision and control with Impact Poly Dead...

-

Dead Blow Sledge Hammers

Elevate your heavy-duty work with our Dead Blow Sledge Hammers, the definitive...

-

Hammer Racks

Impact Poly Hammers Ltd. Racks. Including hand-held and sledge series options.

-

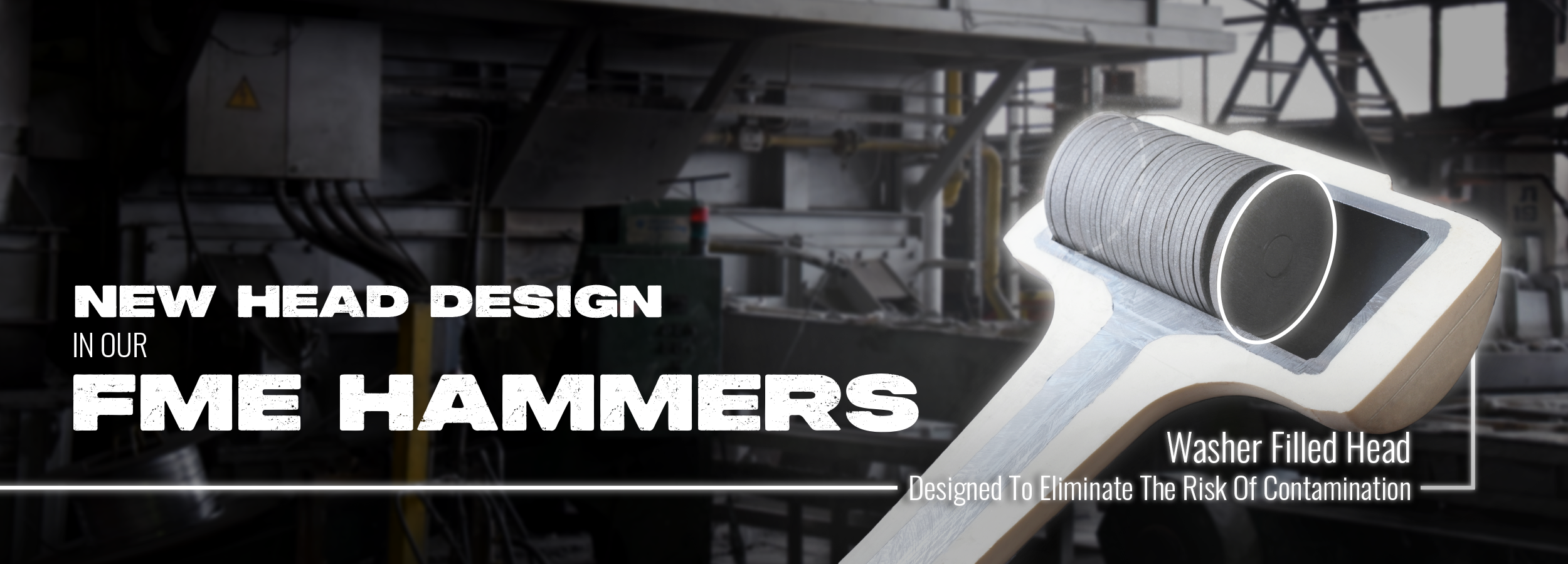

White Dead Blow Hammers for Foreign Material Exclusion (FME) Industries

The white dead blow hammer is an essential tool for industries that...

What people say...

-

-

Fortis HD

https://www.fortishd.com/iph-dead-blow-hammers-engineering-review/Impact Poly Hammers has considered several design and manufacturing details to craft one of the most versatile and robust dead blow hammers to tackle mild and serious heavy-duty tasks.

-

Last Best Tool via YouTube

https://youtu.be/aniw1SlgHkA?si=eAtFAQNsFQs4qywnIMPACT Poly Hammers: A welcome dead blow from the north. Loads of sizes. Top performance. Orange!

-

Mitch via Facebook

Best damn hammers there are. Extremely durable. Had mine for 15 years and no chipping on the end!!

-

Leeland in Regina

Stanley, Snap-On, Jet. They all have the dead-blow hammers, but nobody has anything like the Impact product – it outlasts every other one. The Milwaukee product is not even close. One guy I know went through 12 Snap-On hammers in the same year. He has now had an Impact hammer for 7 to 8 months and he says it is hardly nicked.